HOW IT WORKS

A SIMPLE BUT ACCURATE

MECHANISM FOR

GUARANTEED RESULT

The micronisation and drying process on which the TRITOR system is based occur through friction and impact, using steel balls operated by hammers set inside the treatment vat, which exercise such a powerful pressure that the materials are instantly crushed, destroying the bacterial flora, eliminating bacteria and odours and contributing to dehydration.

Let’s have a close look at the operation.

A

The steel balls hit the fragments of material and carry them towards the wall of the container at a speed ranging from 20 to 53 m/s.

B

The impact of the balls crushes the material causing an immediate expulsion of the liquids as vapour, without condensation.

C

The ball that caused the expulsion of the water bounces towards the centre of the container. Therefore, the material is fragmented.

D

Before the material falls to the bottom, another ball hits it again, reaching an increase in temperature that can significantly exceed 100°C.

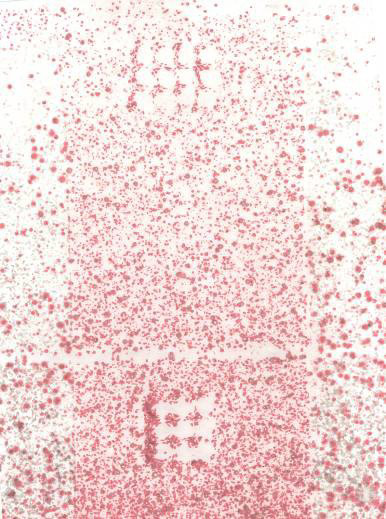

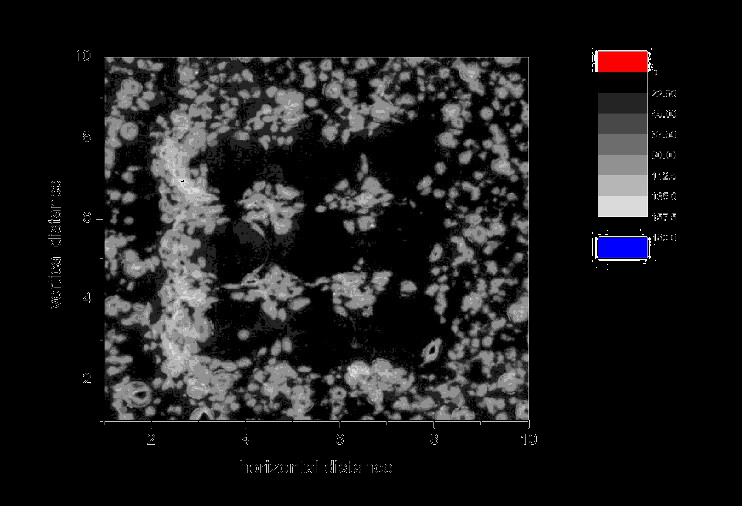

Image of the mill internally taken with Pressurex (www.sensorproducts.com) sensor film: the pink dots are those where the balls have transferred their kinetic energy reaching impact pressures above 200 MPa (2000 atmospheres); to the right, the grey tone scale from 0 to 200 MPa.