USES

A RESOURCE AVAILABLE TO PUBLIC AND PRIVATE SECTORS

TRITOR technology is available and it has been tested successfully directly on the production sites of many public and private companies.

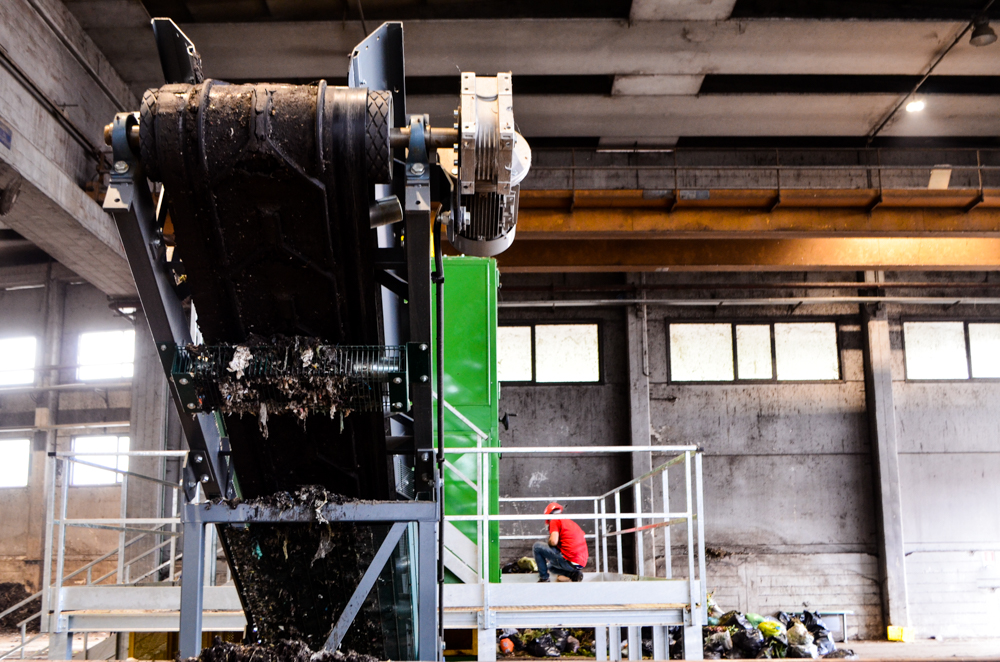

A real revolution in the treatment of various types of waste, including unsorted general waste, dry fraction, organic and sludge fraction.

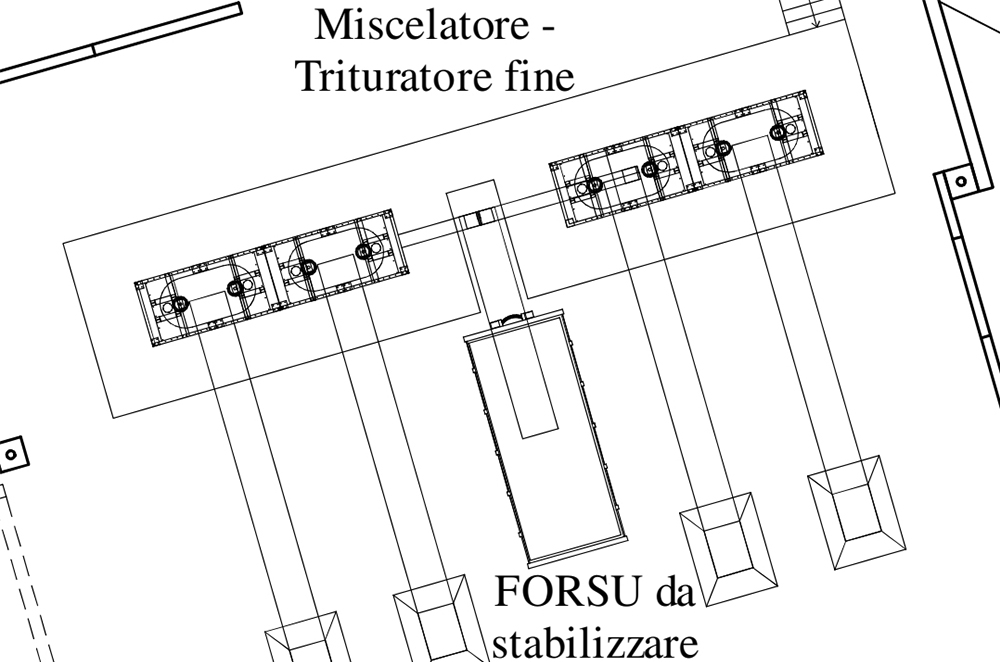

The machinery is modular, therefore it is extremely versatile. It consists of one or more treatment jars that can be installed in parallel to meet the quantity requirements most suited for each operator.

Furthermore, it easily integrates downstream of the existing systems in MBT plants, optimising the production process, increasing the rotation of the materials and reducing disposal costs.

All this translates into a net increase in profit.

WASTE BECOMES

A TRUE VERSATILE TECHNOLOGICAL RESOURCE

VERSATILE TECHNOLOGICAL

TRITOR technology is available and it has been tested successfully directly at the production sites of many public and private companies. A real revolution in the treatment of various types of waste, including unsorted general waste, dry fraction, organic and sludge fraction.

MODULAR

TECHNOLOGY

The machinery is modular, therefore it is extremely versatile. It consists of one or more vats for treatment that can be installed in parallel to meet the quantity requirements most suited for each operator.

OPTIMIZATION OF THE PRODUCTION PROCESS

TRITOR technology is easily integrated downstream of existing Mechanical Biological Treatment systems optimising their production process and increasing the rotation of materials

PROFITABILITY

Thanks to TRITOR technology, disposal costs are considerably reduced. The result is an increase in profitability for the company, whether public or private

Landfills

Volume of Bocca landfill reduced – Production of SSF

MBT

Biostabilization accelerator – Production of SSF

Composting Plants

Biostabilization accelerator – Production of SSF – Sludge treatment

Waste Transfer Stations

Reduction of weight and volume of material sent to treatment plants

SSF production systems

Volume of Bocca landfill reduced – Production of SSF